Can Repalletizers | Automated Can Repalletizing Systems

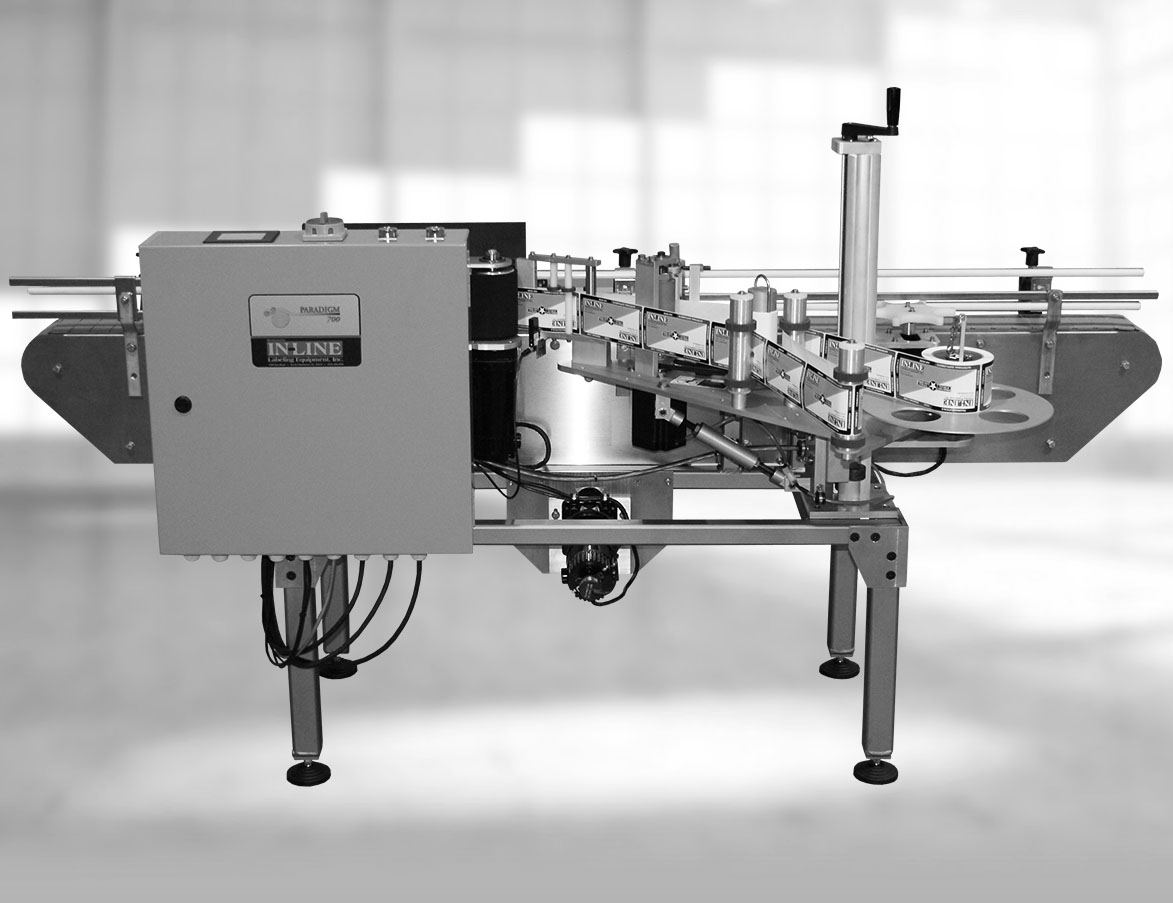

Our depal/repal systems are designed for companies specializing in can sleeving, labeling, printing or other forms of decorating. We bring our automation expertise, unparalleled performance, and simple operation all the way through the line with our bulk can repalletizers.

Descripción

Features

- Dimensions vary depending on configuration

- Semi-Auto uses can metering & controlled stop for layer formation

- Full-Auto has automatic layer formation

- Manual tier sheet layers on semi-auto

- Automatic tier sheet layers on full-auto systems

- Accommodates multiple can sizes with simple part changeover

- Speeds up to 600CPM (with proper conveyance and accumulation)

- Load/unload with pallet jack

- Minimal air consumption (3-4 CFM at 80PSI)

- Siemens PLC platform with touchscreen controls

- Custom colors available

Full-Auto System

- Repal Operators: 1 – Part time monitoring. Top frame placement for pallet change

- Line speed: 10 – 600 CPM

- Full Height: 21 layers of 12oz, 18 layers of 16oz

- Half Height: 11 layers of 12oz, 9 layers of 16oz

- Custom Height: Varies, depending on costumer requirements

- Pallet Size: US & Canadian standard (44″ x 56″) & custom

Semi-Auto System

- Repal Operators: 1 – 2 depending on line speed

- Line speed: 10 – 220 CPM

- Full Height: 21 layers of 12oz, 18 layers of 16oz

- Half Height: 11 layers of 12oz, 9 layers of 16oz

- Custom Height: Varies, depending on costumer requirements

- Pallet Size: US & Canadian standard (44″ x 56″) & custom

Características

- Dimensions vary depending on configuration

- Semi-Auto uses can metering & controlled stop for layer formation

- Full-Auto has automatic layer formation

- Manual tier sheet layers on semi-auto

- Automatic tier sheet layers on full-auto systems

- Accommodates multiple can sizes with simple part changeover

- Speeds up to 600CPM (with proper conveyance and accumulation)

- Load/unload with pallet jack

- Minimal air consumption (3-4 CFM at 80PSI)

- Siemens PLC platform with touchscreen controls

- Custom colors available

- Repal Operators: 1 – Part time monitoring. Top frame placement for pallet change

- Line speed: 10 – 600 CPM

- Full Height: 21 layers of 12oz, 18 layers of 16oz

- Half Height: 11 layers of 12oz, 9 layers of 16oz

- Custom Height: Varies, depending on costumer requirements

- Pallet Size: US & Canadian standard (44″ x 56″) & custom

- Repal Operators: 1 – 2 depending on line speed

- Line speed: 10 – 220 CPM

- Full Height: 21 layers of 12oz, 18 layers of 16oz

- Half Height: 11 layers of 12oz, 9 layers of 16oz

- Custom Height: Varies, depending on costumer requirements

- Pallet Size: US & Canadian standard (44″ x 56″) & custom

¿Interesado en Can Repalletizers | Automated Can Repalletizing Systems?

Completa el formulario y nuestro equipo de expertos se pondrá en contacto contigo para ofrecerte la mejor solución.

Información de Contacto

Teléfono

+1 305 827-9480Productos Relacionados

Enjuagadoras Pre-Fill Ska Fabricating | Limpieza de Botellas y Latas

Las enjuagadoras pre-fill de Ska Fabricating limpian botellas y latas antes del ...

Sistemas Post-Fill Ska Fabricating | Empaque Después del Llenado

Los sistemas post-fill de Ska Fabricating ayudan a mover y organizar los envases...

Ska Fab Microbus | The Smallest & Most Compact Can Depalletizer

Capable of speeds up to 30 CPM, the Microbus depalletizer is optimized for the s...

The Nimbus | Small Footprint Depalletizer for Beverage Lines

The Nimbus combines the best features from two of our best-selling machines to c...